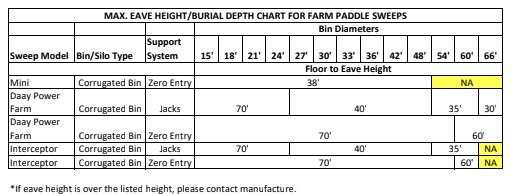

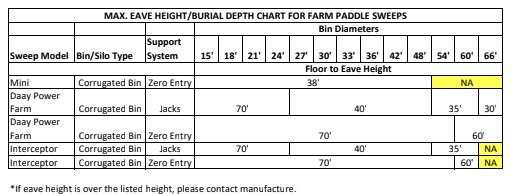

Rule of thumb the Mini-Sweep is good up to a 10-ring bin (38ft). If the eave is any higher, they need a Daay Farm Power sweep

Sweep Burial Depth Chart

Grain Bin Paddle Sweep has a maximum capacity of 2,200 bushels per hour.

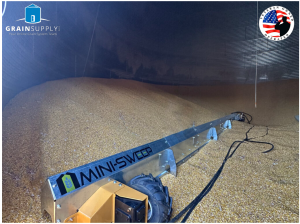

Gently & Evenly Move Grain To Bin Sump With A Single Pass

This non jack system allows for minimal entry into a grain bin during the unloading process creating a safer environment on the farm.

-

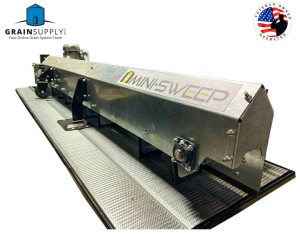

Power Sweep Features:

- Manufactured to fit in bins 15' to 48' in diameter.

- Up to 2,200 bushels per hour capacity.

- Capable of being connected directly to new or existing 8” or 10” round tube or U-trough unloads.

- Electric motor option available for bins without a center gearbox or existing sweep.

- Patented inclined head section available for off-center sumps.

- Aggressive shell design allows the sweep to thrive while digging itself out of a grain avalanche.

- Automatically adjusts to uneven floor height with a patented flexible joint and stabilizer arms.

- DIY: Assembly required.

Powered by the power gearbox so there is no 2nd motor or power cords. The drive is driven by the paddle chain, eliminating the need for another power source.

It has a flexible pivot joint and stabilizer arms to allow the sweep to move independently from the gearbox. This allows the sweep to adjust to variations in the floor height.

The adjustable stabilizer arms accommodate variations in the bin size and out of roundness.

The flexible pivot joint transfers the power from the gear box to the sweep and gives you the flexibility to slow down or speed up the speed of the paddle chain to better match the Bushels per hour of the reclaim system. This will prevent overloading of the sweep and reclaim due to excessive capacity.

The inclined pivot section allows the grain to flow the sump, so not matter if your sump is offset of center of your bin, the sweep will be able to achieve max capacity at any position in the bin.

Eliminates the labor intensive process of sweeping the remaining 1-2” of grain that an auger based sweep would typically leave behind.

The rubber drag helps clean the floor for minimal sweeping.

With a single, segmented 5"x8"x15" tire, the drive wheel is closer to the center of gravity, so the weight of the sweep is transferred to the tire better eliminating the need for a weight bracket.

For other sweeps visit: Grain Supply Powersweep Unloads

Reviews

There are no reviews yet